Daltons Wadkin, a Nottingham-based multi-material machine solution supplier, has expanded its team by hiring a specialist to lead the company’s fiber laser and sheet metal offering.

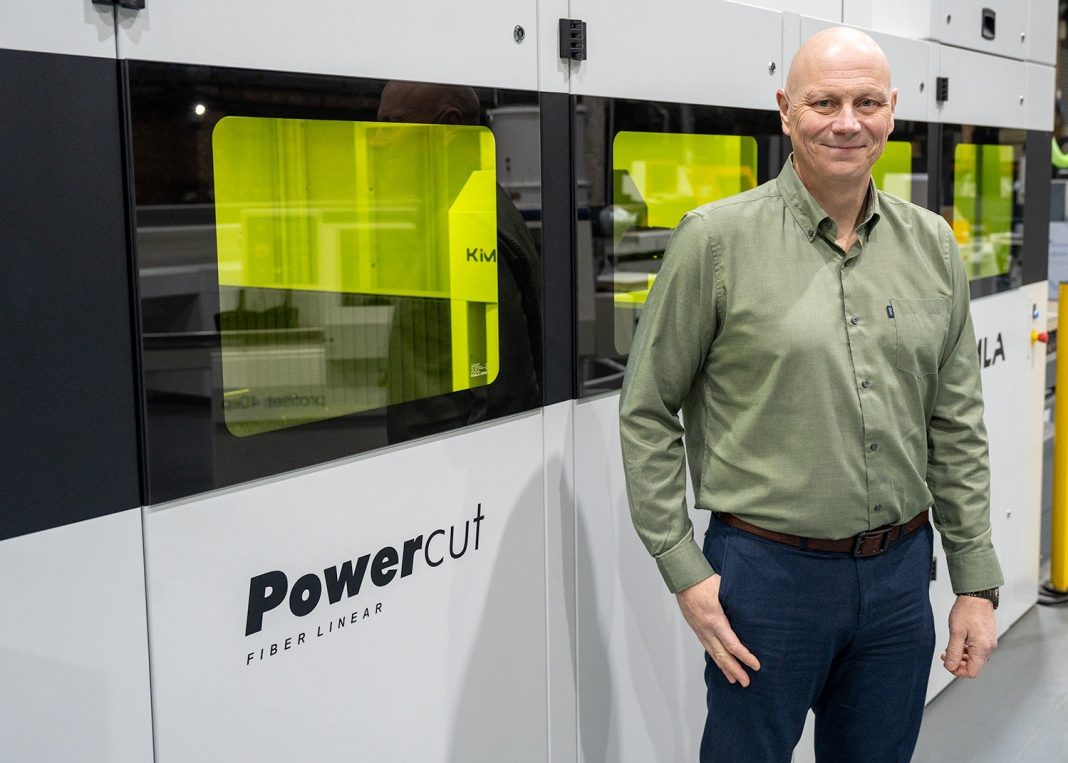

Adrian Wright has joined the family-run business as a Fiber Laser Sales Manager, bringing over three decades of experience in the fiber laser and sheet metal market, working for some of the most prestigious names in the industry.

He will now lead on managing Daltons Wadkin’s exclusive partnership with CNC and fiber laser producers, Kimla, to grow the fiber laser installations across the UK and Ireland.

In 2022, Daltons Wadkin announced that it had become the sole distributor for Kimla’s range of CNC routers and fiber laser cutters, following a 15-year partnership.

Managing Director Alex Dalton said: “We’re excited to welcome Adrian to lead our fiber laser division. His deep expertise in the sheet metal arena and fiber laser sector is exactly what we need to propel our growth.

“Kimla’s fiber laser technology is truly cutting-edge, supported by our robust network of trained engineers across the UK and Ireland. Adrian’s appointment is the final piece, allowing us to bring these components together and advance confidently in the market with a dedicated expert.”

Adrian Wright said: “I can’t wait to join the team at Dalton Wadkin, and especially the fantastic opportunity to show customers and companies alike the Kimla range of products, including the incredible Kimla Fiber Lasers machines.

“Kimla and Dalton Wadkin have built up a tremendously close working relationship over the past 15 years, and I intend to fully utilise and embrace introducing these machines to customers.

“Key to our success will be showcasing our machines to their fullest potential via live demonstrations in either Nottingham or Poland. Kimla are not just machine builders but are true innovators invested in developing the fiber laser machine from the ground up.

“Designing and manufacturing their own linear motors, coupled with their unique machine design, are just two examples of what makes a Kimla Fiber machine cut materials faster with unrivalled part quality.”