Vestatec UK, a specialist in metal forming and assembly, has made a seven-figure investment to improve its manufacturing facility in Nottingham.

The Colwick-based business, and supplier to some of the world’s leading vehicle manufacturers, has invested almost £2 million to expand the 20,000 sq ft facility and enhance its global service offering.

Mike Bylina, Managing Director at Vestatec, said: “This is a truly exciting development in Vestatec’s ambitious growth plans as we continue to be a leading Tier 1 supplier to the global automotive supply chain.

“Our Nottingham-based site is a hub for creating bespoke interior trim for some of the most prestigious brands in the world, which is a true testament to the city’s legacy in UK manufacturing.”

Vestatec is one of the only manufacturers in the UK to specialise in highly complex metal forming, etching and assembly, creating precision components to meet the requirements of high performance and aesthetic applications.

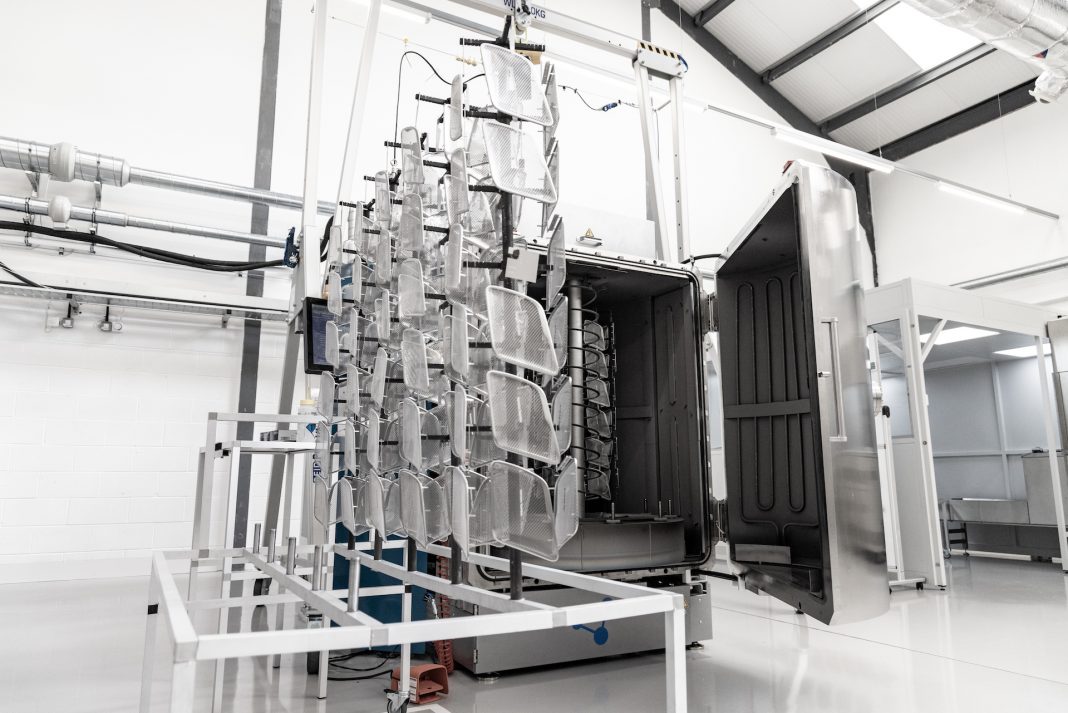

Part of its seven-figure investment includes the development of its new Physical Vapour Deposition (PVD) coating facility and the company’s first robotic system to offer more affordable and flexible services for both new and existing customers.

Mike continued: “In recent years, we have invested heavily in the right people, tools and equipment to elevate our capabilities.

“We believe that this next stage will help to cement Vestatec’s position within the automotive industry, while broadening our service offering to support a variety of other sectors.

“By developing our factory, we are able to expand our capabilities and bring a core service in-house, removing the need for support from additional suppliers and taking another step out of the logistical process for our customers. The additional equipment will also allow us to speed up production and reduce costs for our customers.

“Our next steps are to invest in the future and continue on our mission to ensure Vestatec is the partner of choice for metal forming and specialist coatings across the globe.”