Researchers at Rolls-Royce University Technology Centre (UTC) in Manufacturing and On-Wing Technology at the University of Nottingham have developed ultra-thin soft robots, designed for exploring narrow spaces in challenging built environments.

These advanced robots, featuring multimodal locomotion capabilities, are set to transform the way industries, such as power plants, bridges and aero engines, conduct inspections and maintenance.

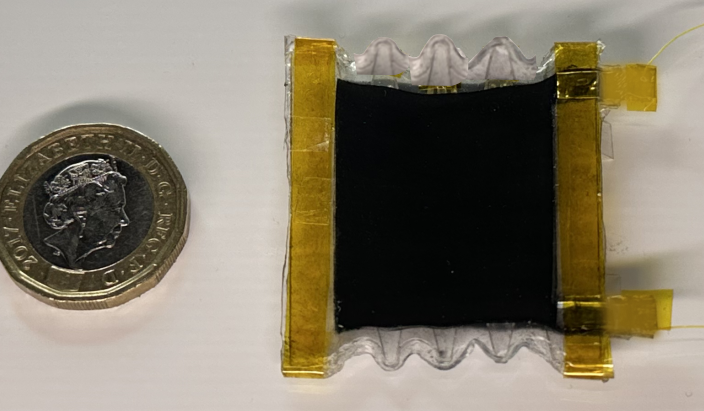

The innovative robots, known as Thin Soft Robots (TS-Robots), boast a thin thickness of just 1.7mm, enabling them to access and navigate in confined spaces, such as millimetre-wide gaps beneath doors or within complex machinery.

TS-Robots are equipped with a unique sandwich structure driven by dielectric elastomers, allowing them to crawl, climb, swim, and transition between solid and liquid domains. This adaptability makes them ideal for complex environments that include multiple obstacles across various terrains.

Dr Xin Dong, the project’s principal investigator, who initialised the idea, said: “Our TS-Robots are designed to tackle the scientific challenges of multimodal locomotion in soft robotics, particularly when encountering obstacles such as narrow gaps, trenches, walls, and liquids along their navigation paths.

“Unlike conventional robots, which face significant limitations in these environments, our technology offers a potential breakthrough for exploring difficult and complex terrains.”

Notably, the Thin Soft Robots exhibit outstanding performance in terms of output force and speed, achieving forces up to 41 times their weight and speeds of 1.16 times their body length per second.

This exceptional capability enables them to collaborate with multiple TS-Robots or even with other robots, such as drones, enhancing their functionality in tasks such as inspecting challenging environments or delivering goods.

Preliminary tests have already demonstrated the potential of the Thin Soft Robots in real-world applications, including the inspection of electrical generators of advanced hybrid-electric power systems. In this application, the robots successfully navigated the narrow air gap between the rotor and stator of a generator, a feat that traditional tools and robots cannot achieve.

Professor Dragos Axinte, Director at the Rolls-Royce UTC in Manufacturing and On-Wing Technology, added: “The next generation of clean power systems presents new challenges for their inspection and maintenance. We are delighted to see these thin soft robots bringing the possibility to address these challenges and contribute to the future of net-zero.”

With these promising results, the research team plans to further optimize the robots’ design and explore new applications in sectors such as aerospace and energy maintenance and nuclear decommissioning.